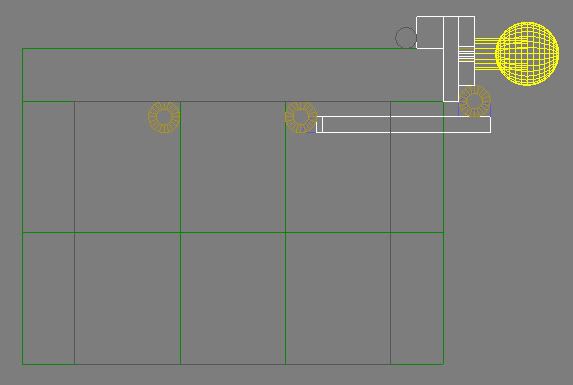

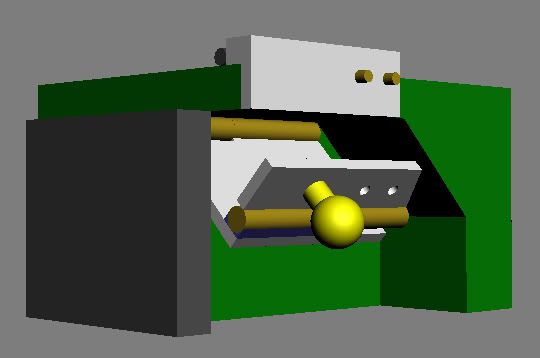

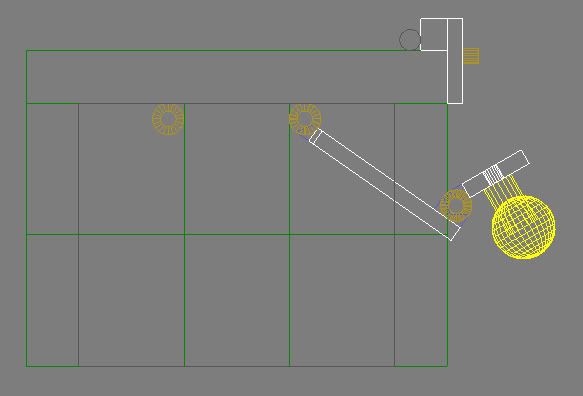

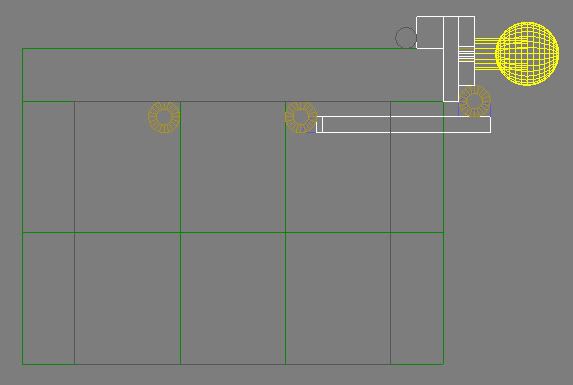

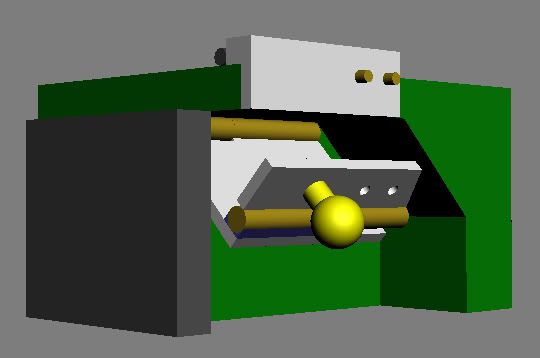

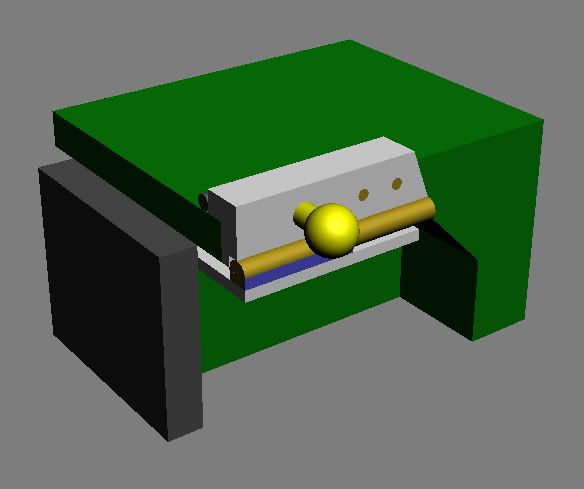

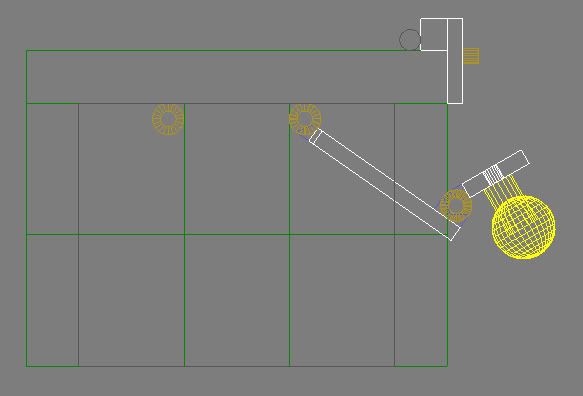

Righto, here we go! I knocked these diagrams up in 3DS Max, they're very simple but show the important bits of the mechanism I think

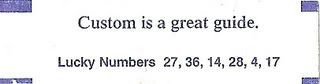

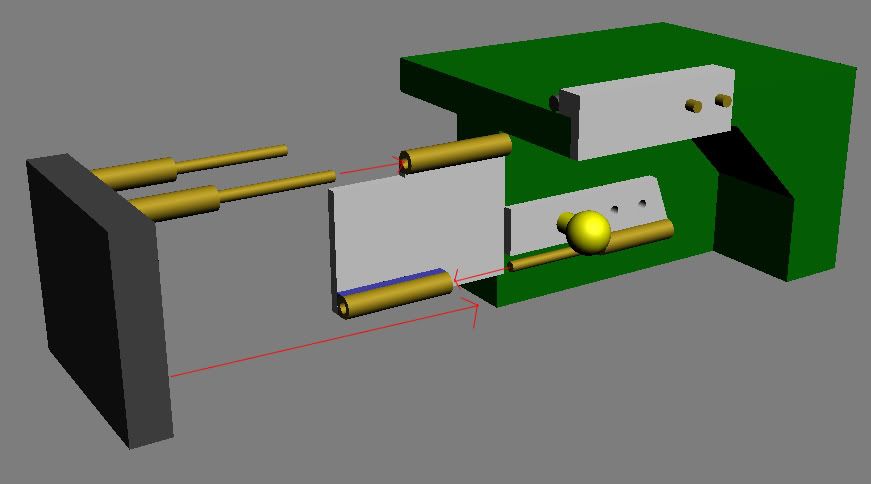

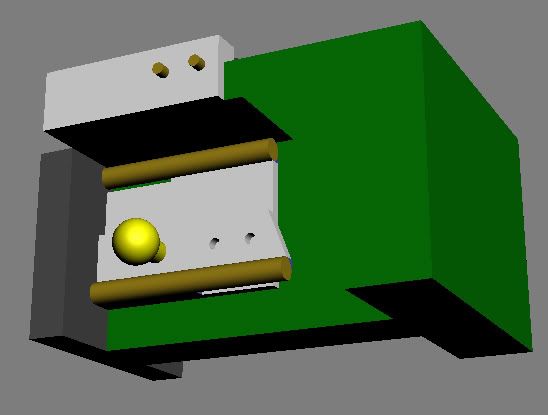

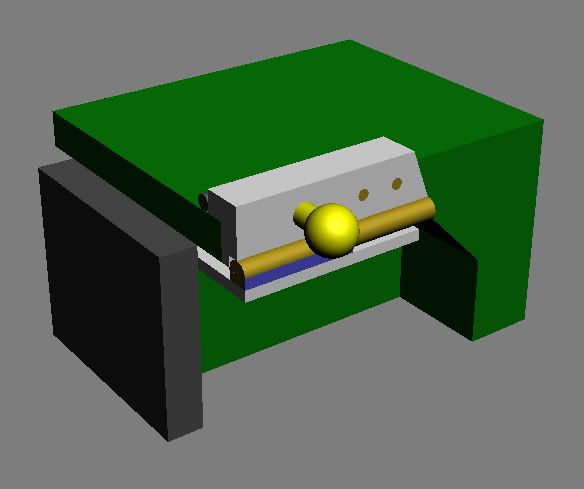

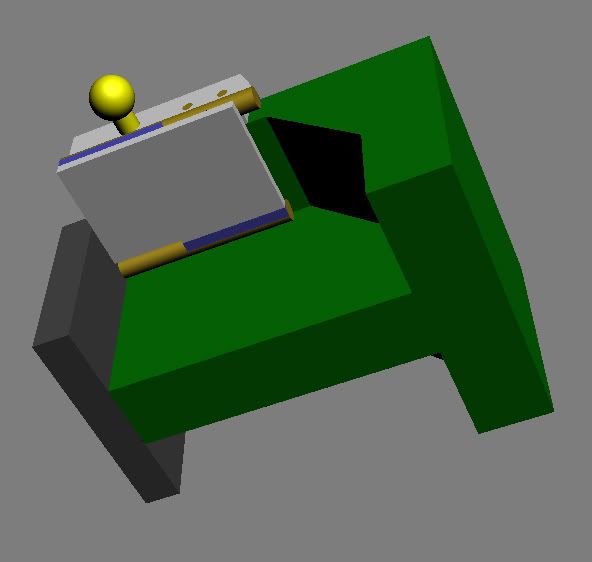

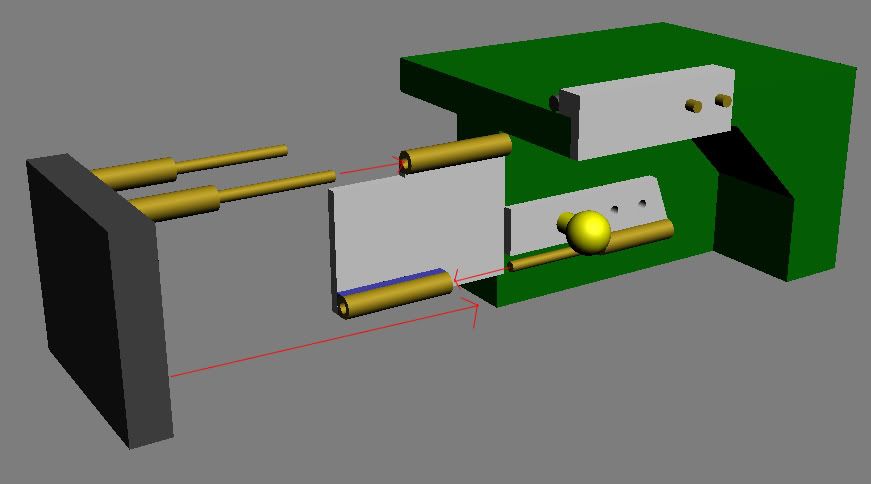

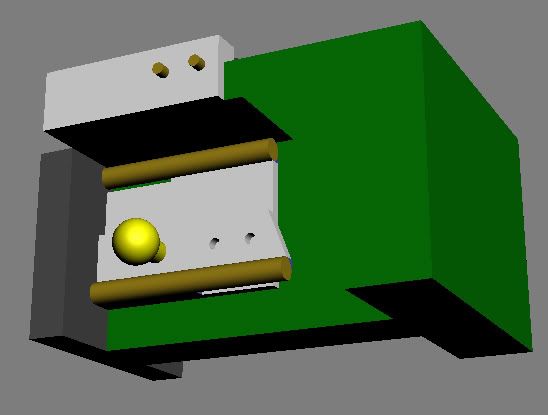

The green bit is obviously Overhaul's main torso, and the grey plate at the front is his chest plate, which is fixed into place normally once the axles are glued onto it. The gold coloured parts are brass rod and tubing, and the white areas are plasticard. The blue areas are where you'll need some damn good adhesive to fix the tubing to the plasticard! I used superglue and it sufficed, but I had to re-stick them more times than I care to remember because it's such a minimal area of contact. If anyone can think of better materials to use, let me know, as I just used what I had to hand

Oh yeah, and the ball for the shoulder joint is off the toy, mercilessly ripped out of it's mounting in the door plate!

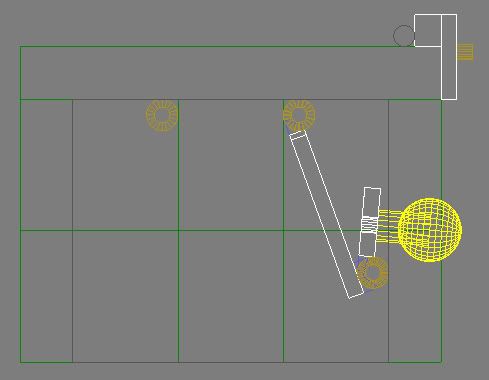

Hopefully the pics are pretty self-explanatory, tho I should state that it's not properly to scale!

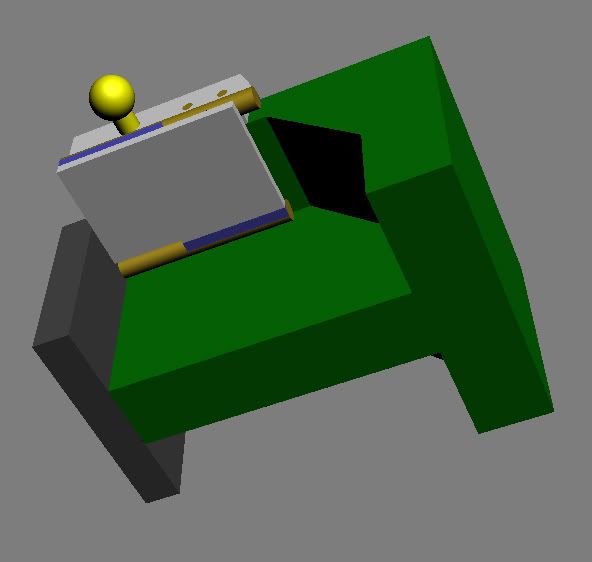

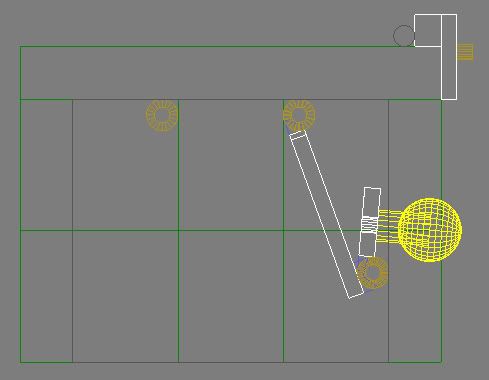

The most important measurement is the larger of the two plasticard plates in the hinge, as it needs to be wide enough to reach right across the underside of Overhaul's roof, and bring the second hinge out at the side so the plate with the ball on can be placed vertically at the side of the roof. I added some plasticard to the roof to make it a bit thicker at the edge (needed because his shoulder sticks out a bit, so the door plate needed some extra stuff to sit on), and then added two small pegs, which fit into the holes in the second plate to lock it in place. The door sections also have matching holes in an extra piece of plasticard at the top, which locks them in place in vehicle mode

Unless you can find something thinner and still strong to replace the plasticard, this WILL make Overhaul's shoulders stick out of the cavity in vehicle mode, so you'll need to mod the door plates as well. Having said that, there's most likely several other ways this basic approach could be modified, so if anyone comes up with a better idea, let me know!

Finally, I found that even when I got him to hold together, he still requires a gentle touch. The tubing doesn't fix all that well to the plasticard, even with filler adding more surface area to the contact. I drilled a hole in the smaller plate where the ball fits, and added a short peg that runs into the shaft on the ball, for strength. It may be possible to find small modellers hinges that could work in this scenario, thus eliminating the need to construct your own, but again, I was working with what I had at the time

Hope this helps folks, any questions, just ask

Assembly, front angle

Assembly, rear angle

Completed assembly

Assembly halfway between modes

Assembly extended and locked to shoulder mount

Assembly extended, lower view

Assembly retracted, front view

Assembly extending...

Assembly extending more...

Assembly extended and locked